- Home

- About Us

- Products

Chromatography Liquid Chromatography (LC) Gas Chromatography (GC) Thin-layer Chromatography(TLC)

Spectrometer AAS ICP Raman Spectrometer FT-IR Spectrometer UV-Vis Spectrophotometer Terahertz Spectrometer Infrared Spectrometer Terahertz Imager Spectroscopy Consumables Others

Mass Spectrometer MALDI-TOF-MS GC-MS ICP-MS

Physical Property Analysis Instrument Differential Scanning Calorimeter Melting Point Apparatus Refractometer Polarimeter Viscometer Density Meter Colorimeter/Turbidimeter

Sample Preparation Laboratory Water Purification System Evaporator Extractor Centrifuge Mixer Pipette Digester Others

Life Science Safety Cabinet Freezer PCR Microplate Reader Incubator Others

Elemental Analysis Kjeldahl Apparatus TOC Analyzer Carbon&Sulphur Analyzer Metal Analyzer Others

Lab Consumables Biochemical Consumables SPE Cartridges QuEChERS Kits

PPE Instruments Oxygen Concentrator Sterilizer

Environmental Measurement Iinstruments Gas Measurement Device

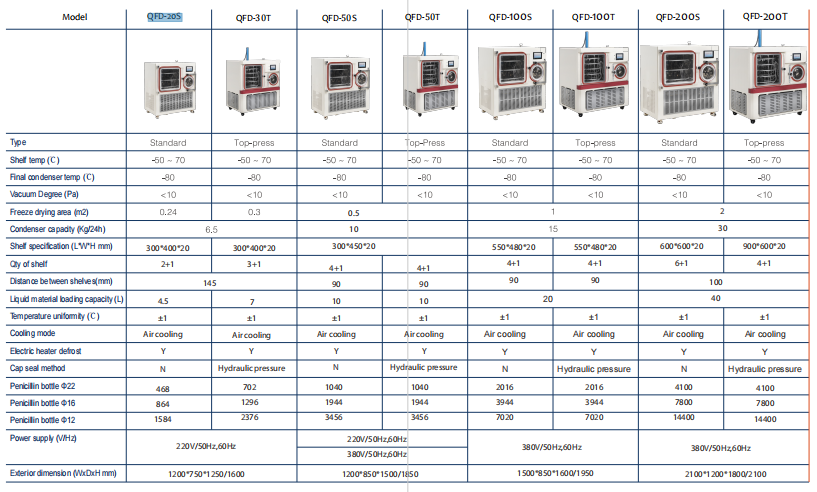

Others Magnetic Content Analyzer Glassware Washer Capping Machine Freeze Dryer Burette PH Meter Calorimeter Titrator Nitrogen Generator Automatic Drop Point and Softening Point Tester

- Solution

- Support

- Contact Us

-

- Language